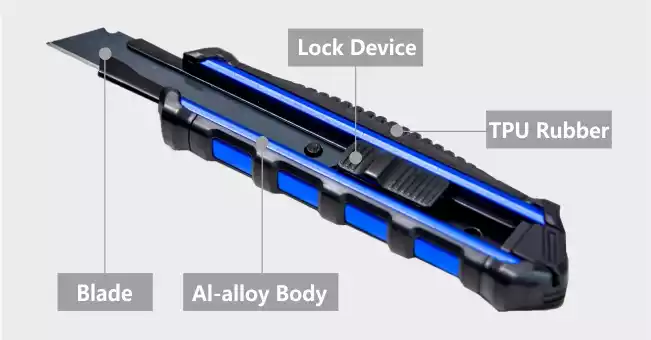

18mm Al-alloy Single Blade Utility Knife

18mm Al-alloy Single Blade Utility Knife

Model: MC-202

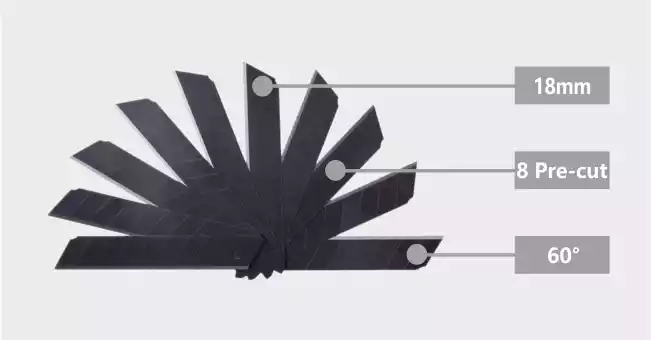

Blade: 18mm Black Blade

Materials: Al-alloy+Steel

Weights:105g/Pcs

Packing:6Pcs/Box, 24Box/Carton

Video

_Product

_Parameter

_FAQ

_Download

_E-mail

_Nav

_

Widely Applications

Product Feature

Front & Back Side

18mm Blade Blade

Good Cutting

Spare Parts

Good Handle Feeling

105g Weight

The manual v-groove cutting ruler is a product upgraded from the manual v-groove cutter. It consists of four parts: an aluminum alloy guide ruler, slotting positioning lines, a slideable slotting module, and fixed end caps at both ends. The slideable v-groove cutting module is connected to the aluminum alloy guide ruler through four wheels, and the v-groove cutting positioning lines are fixed on the fixed end caps at both ends. The end caps and the aluminum alloy guide ruler are fixed together with self-tapping screws. The v-groove cutting positioning lines pass through the center of the v-groove cutting component, achieving the purpose of rapid positioning and thus realizing quick and accurate slotting.

The manual v-groove cutting ruler is very convenient to use, allowing customers to achieve quick positioning through the slotting positioning lines on the ruler. The slideable slotting module on the ruler enables rapid v-groove cutting . Each v-groove cutting ruler comes with two replaceable v-groove cutting modules, easily achieving v-groove cutting angles of 90 degrees and 120 degrees.

Generally, the steps for using the v-groove cutting ruler are as follows:

First, determine the position where v-groove cutting is needed based on the content of the drawing, and mark it on the back of the board.

Second, align the positioning line of the v-groove cutting ruler with the marked points on the back of the drawing, pull the v-groove cutting component, and complete the v-groove cutting work.

From the above description, it is not hard to see that the new quick v-groove cutting ruler features convenient positioning and quick v-groove cutting , greatly improving the efficiency and quality of v-groove cutting to ensure a good slotting effect.

On the manual v-groove cutting ruler, the blade and positioning lines may need to be replaced periodically due to usage. The related precautions are as follows:

First, when replacing the blade, be sure to remove the v-groove cutting mold from the v-groove cutting ruler before changing the blade.

Second, when replacing the positioning line, try to tighten the positioning line before twisting the screw to clamp and fix it.

In the actual use of the manual v-groove cutting ruler, besides the need to regularly replace the blade and positioning lines, there may also be issues with insufficient v-groove cutting precision and loose positioning lines. Generally, for the problem of insufficient v-groove cutting precision, it can be solved by loosening the fixing screws of the end cap and moving the end cap's sheet metal to improve the v-groove cutting positioning precision. As for the issue of the positioning line being somewhat loose, it needs to be tightened again and fixed firmly with screws, thus solving some of the minor problems that may occur in daily use.